The industrial landscape is undergoing a metamorphosis, driven by the transformative power of the Internet of Things (IoT) and the dawn of Industry 4.0. At the heart of this revolution lies seamless communication between a myriad of machines and devices that populate the factory floor. This symphony of data exchange hinges on two crucial technologies: Remote Input/Output (I/O) modules and Industrial IoT (IIoT) Gateways. Let's delve into the intricate dance between these technologies and how they unlock the true potential of Industry 4.0.

Demystifying Remote I/O Modules

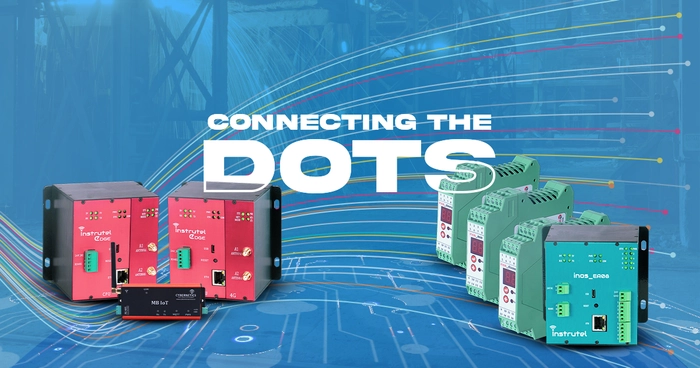

In today's era of smart work, remote I/O modules serve as extended hands for the factory's control system, enabling signal collection and control from sensors and actuators spread throughout the facility. Connected to a central controller via communication protocols like Modbus or Ethernet, these modules enable real-time monitoring and control, even for distant locations within the factory.

IIoT Gateways: The Vital Link

IIoT Gateways serve as the critical bridge between the bustling industrial world and the ever-evolving information age. IIoT Gateways are devices that serve as intermediaries between sensors, machines, and the cloud in Industrial Internet of Things (IIoT) systems. These gateways collect, process, and transmit data from connected devices to cloud-based platforms for analysis and action. IIoT Gateways play a crucial role in facilitating real-time monitoring, analysis, and control of industrial processes, leading to improved efficiency, productivity, and decision-making in manufacturing environments.

The Power of Integration

Visualise an expansive factory floor adorned with strategically placed sensors and actuators. Remote I/O modules, serving as the backbone, seamlessly collect data from these dispersed devices. The IIoT Gateway assumes the role of the central nervous system, consolidating data from multiple remote I/O modules and perfectly transmitting it to the "brain" – cloud-based analytics and control applications. This harmonious integration heralds a new era of possibilities for Industry 4.0 :

● Maintaining Operational Efficiency: Real-time data from remote locations empowers proactive maintenance strategies. By anticipating equipment failures and optimising production processes, industries can experience significant gains in efficiency. A study by McKinsey & Company suggests that companies embracing Industrial IoT can achieve a remarkable 3-5% increase in productivity, a testament to the transformative power of this integrated approach.

● Data-Driven Decision Making: The data collected through remote I/O and IIoT Gateways provides valuable insights into machine performance, production bottlenecks, and overall process efficiency. This empowers businesses to make data-driven decisions that go beyond intuition, optimising operations and improving profitability. Imagine being able to identify and address inefficiencies before they significantly impact production – a reality enabled by this powerful synergy.

● Remote Monitoring and Control Unleashed: With remote I/O modules and IIoT Gateways working in tandem, critical processes can be monitored and controlled remotely. This translates to improved flexibility for businesses, enabling faster response times to production issues and ensuring tighter control over geographically dispersed operations.

Benefits Across Industries :

Instrutel,we are a company specialising in modular industrial automation solutions, exemplifies the transformative impact of integrating Remote I/O and IIoT Gateways across various industries:

● Manufacturing: Increased production uptime translates to higher output. Improved quality control ensures consistent product quality, while reduced energy consumption leads to significant cost savings.

● Oil & Gas: Enhanced monitoring and control of pipelines, remote wellheads, and processing facilities translates to improved safety, operational efficiency, and resource management.

● Food & Beverage: Real-time tracking of product temperature throughout the production process ensures food safety and optimises processing times, leading to reduced spoilage and improved product quality.

● Building Automation: Efficient management of HVAC systems, lighting, and other building controls optimises energy usage and creates a more comfortable and sustainable work environment.

Challenges and How Instrutel Addresses Them in Integrating Remote I/O and IIoT Gateways

The synergy between Remote I/O modules and IIoT Gateways unlocks a treasure trove of benefits for Industry 4.0, but navigating the path to this integration isn't without its hurdles. Here's a breakdown of the key challenges and how Instrutel tackles them:

Challenge : System Design Complexity

Selecting the right hardware: Choosing compatible Remote I/O modules and IIoT Gateways that match specific application needs can be overwhelming.

Ensuring seamless communication: Configuring the system for optimal performance and ensuring smooth data exchange between components requires technical expertise.

Instrutel's Solutions:

User-friendly design: Instrutel prioritises intuitive design principles in both their Remote I/O modules and IIoT Gateways, simplifying installation and configuration.

Comprehensive support: They offer extensive support resources like documentation, tutorials, and customer service to guide users through the process.

Modular architecture: This allows businesses to select the specific I/O modules needed and integrate them seamlessly with the IIoT Gateway for a customised solution.

Challenge : Integration with Legacy Systems

Compatibility issues: Existing industrial infrastructure may not be readily compatible with newer IIoT technologies, creating integration challenges.

Instrutel's Solutions:

Modular design for seamless integration:Instrutel's I/O modules boast a modular design, allowing them to interface with a wide range of existing equipment and control systems regardless of communication protocols. This eliminates the need for complete system overhauls.

Future-proofing for scalability: The modular approach future-proofs the solution. Businesses can easily add new I/O modules or upgrade the IIoT Gateway without replacing the entire system, ensuring long-term adaptability.

Instrutel is not just in business to make a profit; it aims to solve industrial problems and simplify the process for companies to choose and manage solutions. With India's industrial revolution having a significant impact and positioning the country as one of the greatest economies, Instrutel aspires to be part of this journey towards betterment and automation. Ready to transform your business with unparalleled convenience? Reach out to Instrutel for top-notch IIoT Gateways and Remote I/O solutions