The Indian manufacturing sector is experiencing a significant transformation, driven by automation and Industry 4.0 principles. As factories embrace digitalization, the need for efficient and reliable data acquisition and control becomes paramount. Remote I/O (Input/Output) systems emerge as a critical technology in this scenario, offering a robust and scalable solution for industrial connectivity.

Understanding Remote I/O Systems

Remote I/O systems bridge the gap between a central controller (PLC, DCS) and field devices (sensors, actuators) located away from the control panel. These systems consist of remote I/O modules installed near field devices, connected to a central controller through a communication network. The remote modules handle signal conditioning, data acquisition, and control functions, reducing wiring complexity and simplifying plant layout.

Benefits of Remote I/O Systems for Indian Industries

- Enhanced Efficiency and Productivity: Remote I/O minimises cabling needs, reducing installation time and maintenance costs. This allows for flexible plant layouts, easier system expansion, and faster troubleshooting.

- Improved Data Acquisition and Control: Remote I/O systems offer real-time data acquisition from various field devices, enabling better process monitoring and control. This translates to optimised production processes, improved product quality, and reduced downtime.

- Increased Scalability and Flexibility: Remote I/O systems can be easily expanded to accommodate additional I/O points as production needs evolve. This modularity allows industries to adapt to changing demands without significant infrastructure overhaul.

- Reduced Costs and Increased Safety: By minimising cabling and simplifying wiring, remote I/O systems contribute to lower installation and maintenance costs. Additionally, with fewer cables in the control room, the risk of electrical hazards decreases, improving overall safety.

- Improved Environmental Performance: Remote I/O systems can contribute to a more sustainable manufacturing environment. Reduced cabling translates to lower material consumption, and efficient data acquisition can help optimise energy usage in production processes.

Current Statistics of Remote I/O Systems in India:

- According to a Report by India Industrial Automation Market - Forecast (2022-2027), the Indian industrial automation market is expected to reach USD 23.56 billion by 2027, with a CAGR of 10.22%.

- A Technavio report suggests that the global Remote I/O market will reach USD 5.61 billion by 2026, signifying the growing adoption of this technology.

Applications of Remote I/O Systems in Indian Industries:

Remote I/O systems offer a versatile solution across various Indian industries. Here's a glimpse into their impactful applications:

- Discrete Manufacturing: Remote I/O finds wide application in assembly lines, robotics, and material handling systems for real-time data acquisition and control, optimising production processes.

- Process Industries: These systems are beneficial in oil & gas, chemical, and power plants for monitoring process parameters, controlling valves, and managing actuators remotely, ensuring efficient and safe operation.

- Building Automation: Remote I/O plays a role in smart buildings for controlling lighting, HVAC systems, and security systems across dispersed locations, leading to energy savings and enhanced building management.

- Renewable Energy: In solar and wind farms, remote I/O systems can efficiently manage data acquisition from sensors and control inverters located across large areas, maximising energy production and optimising resource utilisation.

- Defense: Remote I/O systems can be deployed in military manufacturing, managing complex testing equipment for weapons systems and vehicles. Additionally, they can be used for monitoring critical systems in remote locations, like border outposts or communication towers.

- Railways: These systems can be used for train control and monitoring, optimising signal systems for improved safety and efficiency. They can also collect real-time data from sensors on locomotives and tracks, enabling predictive maintenance and preventing potential breakdowns.

Factors Driving the Adoption of Remote I/O Systems in India:

- Government Initiatives: The "Make in India" initiative and Industry 4.0 focus by the government encourage automation and digitalization in manufacturing, propelling the adoption of remote I/O systems.

- Growing Focus on Efficiency: Indian industries are increasingly looking to optimise operations, reduce costs, and improve productivity, making remote I/O systems an attractive proposition.

- Technological Advancements: The development of advanced communication protocols (Ethernet/IP, PROFINET) and wireless technologies (Wi-Fi, Industrial Ethernet) facilitates reliable data transmission in remote I/O systems.

Challenges and Considerations for Indian Industries:

- Initial Investment: Implementing remote I/O systems may require an initial investment in hardware and software. However, the long-term benefits in efficiency, productivity, and cost savings often outweigh this initial cost.

- Technical Expertise: Integrating remote I/O systems requires technical expertise for system selection, installation, and maintenance. Collaboration with experienced automation solution providers is crucial.

- Cybersecurity Concerns: As industrial networks become increasingly interconnected, the risk of cyberattacks rises. Implementing robust cybersecurity measures like firewalls, secure protocols, and user access controls is essential for protecting remote I/O systems.

- Lack of Awareness: While awareness is growing, some Indian companies may not fully understand the benefits of remote I/O systems. Industry education and collaboration can help bridge this knowledge gap.

The Future of Remote I/O Systems in India

The future of industrial automation in India looks bright for remote I/O systems. Here are some key trends to watch:

- Wireless Technologies: The adoption of wireless communication protocols like Wi-Fi 6 and Industrial Ethernet will simplify installation and offer greater flexibility in plant layouts.

- Integration with IIoT: Remote I/O systems will seamlessly integrate with Industrial Internet of Things (IIoT) platforms, enabling real-time data analytics and predictive maintenance for optimizing production processes.

- Increased Focus on Cybersecurity: Manufacturers will place a growing emphasis on robust cybersecurity solutions to safeguard remote I/O systems from potential cyber threats.

Instrutel: Your Partner in Industrial Revolution

Instrutel aspires to be a pioneer in technological advancements for industry and society. Our focus lies on digitalization, data analysis, and resource optimization, empowering businesses to unlock their full potential. By embracing remote I/O technology alongside Instrutel's expertise, Indian manufacturers can:

- Enhance Operational Efficiency: Streamline operations, reduce downtime, and optimise resource utilisation.

- Improve Data Acquisition and Control: Gain real-time insights into production processes and make data-driven decisions for continuous improvement.

- Achieve Scalability and Flexibility: Adapt your infrastructure seamlessly as your production needs evolve.

- Embrace Industry 4.0: Future-proof your manufacturing operations by integrating with advanced automation technologies.

Partner with Instrutel and utilise the transformative power of Remote I/O systems in your industry. Contact us today for a free consultation and explore how we can tailor a solution to meet your specific needs.

Explore Instrutel's offerings tailored to your needs: Remote IOs, featuring the INOS series and Swift. The INOS series comprises two categories distinguished by their communication interface: RS485 and Ethernet.

In RS485 series you’ll get :

- Remote IO 12 Channel Digital Input module

Digital Input Module with Modbus RS485 (instrutel.com)

- Remote IO 12 Channel Digital Output Module

https://instrutel.com/products/inos-d0012-digital-output-module

- Remote IO 8 Channel Analog Input module

https://instrutel.com/products/inos-a80

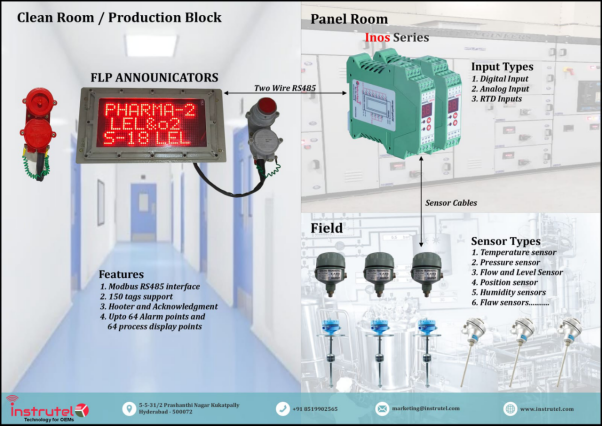

Application Scenario 1:

INOS products along with Process displays used in Shop floors for monitoring critical parameters.

Application Scenario 2:

INOS modules can be used along with Gateways for IIoT applications .

INOS Applications :

- Connect IO modules to display and monitor shop floor parameters

- Expansion IO modules for PLCs / Field Controllers

- Data Logging applications along with HMI

- IIoT applications

Advantages :

- Can be scaled in terms of Number and Type of Ios

- Can be scaled in terms of Technology

- Easy to configure and install

- DIN rail mounting with minimum panel space

In Ethernet Series we have :

- 8 Channel Analog Input Module

https://instrutel.com/products/inos-ea08-high-quality-durable-affordable

- 8 Channel Analog Output Module

https://instrutel.com/products/inos-ea80

Swift

Top RFDIS for IoT Devices: Industry 4.0 Solutions (instrutel.com)

Advantages :

- Totally configurable based on user requirement

- Supports Interfaces like RS485, Ethernet and GSM

- Supports communication protocols like Modbus, ModTCP and MQTT