The electronics industry is a powerhouse of innovation, churning out the devices that shape our modern world. From smartphones that connect us globally to medical equipment that saves lives, electronics are woven into the fabric of our daily lives. A 2023 report by Market Research Future predicts the global electronics manufacturing market to reach a staggering USD 8.5 trillion by 2028, with a growth rate of 8.2%. This explosive growth, however, presents a unique challenge – keeping pace with this ever-expanding demand while maintaining efficiency and profitability.

Struggles Behind the Boom: Challenges Faced by Electronic Manufacturers

While the future seems bright for electronics manufacturing, the road to success is not without its bumps. Here's a closer look at some of the most pressing challenges faced by electronic manufacturers, particularly the numerous small and medium-sized enterprises (MSMEs) that form the backbone of the industry:

● Inventory Management Tightrope: Maintaining optimal stock levels is a constant battle. Running low on critical components can lead to production delays and missed deadlines, costing manufacturers an estimated $400 billion annually according to a study by Aberdeen Group. On the other hand, excess inventory ties up valuable capital and increases storage costs. Surveys revealed that a staggering 42% of manufacturers struggle with maintaining clear visibility and control over their inventory.

● Manual Workflows : The electronics manufacturing process can be intricate, involving numerous steps and complex workflows. Dependence on manual data entry, paper-based systems, and disconnected spreadsheets can lead to errors, delays, and inefficiencies. A PWC study found that human error accounts for a significant portion of these issues, with 30% of production delays attributed to manual processes. Imagine the frustration of misplaced components or errors in production instructions due to human oversight!

● Component Tracking: Keeping track of a vast array of electronic components with varying specifications and suppliers can be a logistical nightmare. Lost track of parts can lead to production stoppages that cost manufacturers an average of $5,600 per minute according to a study by ARC Advisory Group. Delays in locating specific components, and the ever-present threat of counterfeit components infiltrating the production line – these are just some of the headaches faced by manufacturers.

● Automation Hurdle: While large-scale manufacturers heavily leverage automation technologies to boost efficiency, a McKinsey report found that 60% of MSMEs lack the resources and expertise to implement sophisticated automation systems. This leaves them at a disadvantage when competing with larger players in terms of speed and production volume.

NIYAM: A User-Friendly Solution for Streamlining Operations

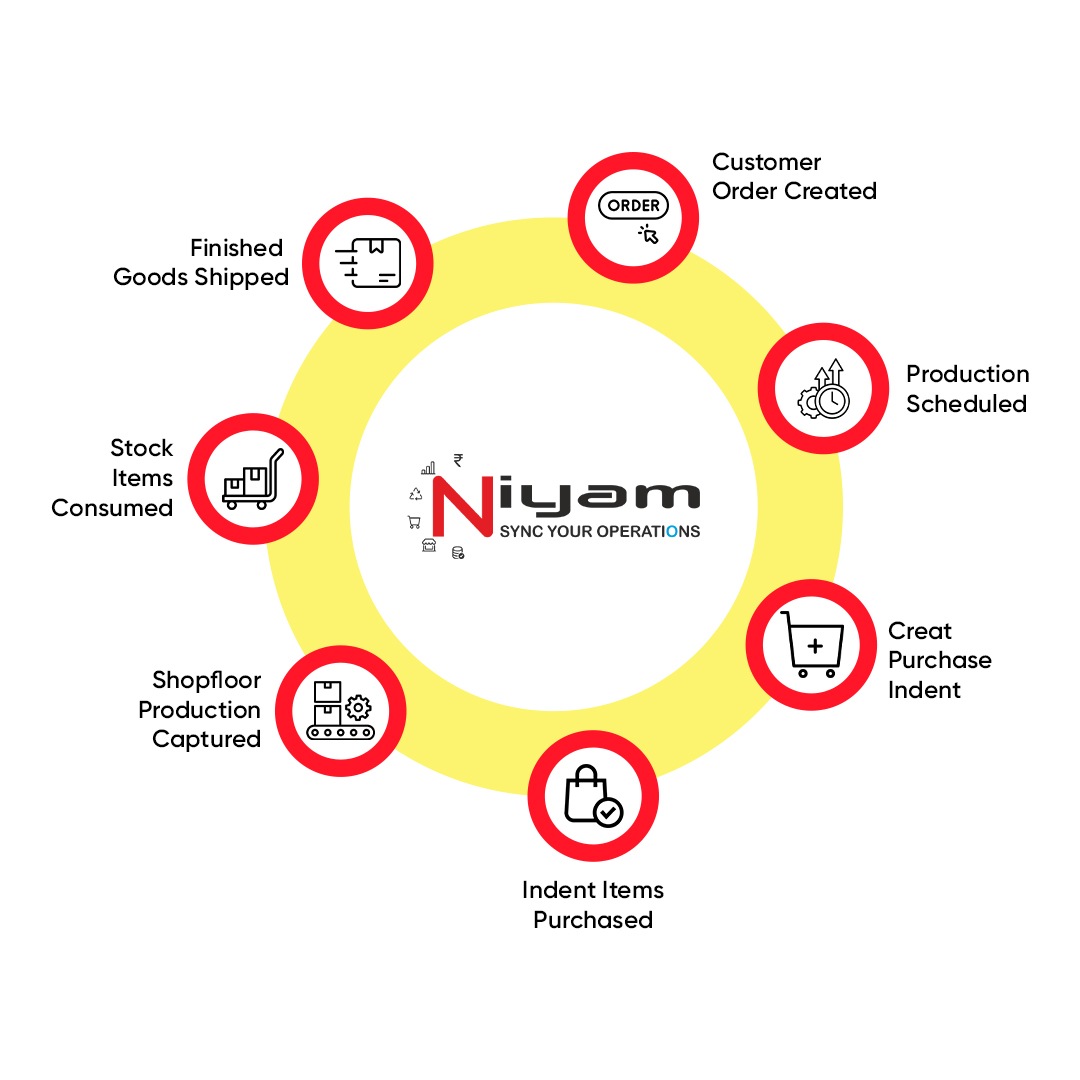

Instrutel's new venture NIYAM is a software that emerges as a powerful tool specifically designed to address these challenges faced by MSME electronic product manufacturers. This user-friendly software streamlines operations and boosts productivity, empowering businesses to thrive in the dynamic electronics industry.

Simplifying Complexity: Key Features of NIYAM

NIYAM goes beyond simply offering a laundry list of features. It provides a cohesive system designed to address the specific needs of MSME electronic manufacturers. Let's delve deeper into some key features and how they translate into real-world benefits:

- Inventory Management Made Easy:

● Low Stock Level Alerts: Never get caught off guard again. NIYAM automatically sends alerts when component stock dips below a predefined threshold, ensuring you have enough materials to keep production running smoothly.

● Negative Stock Restriction: Say goodbye to phantom inventory! NIYAM prevents negative stock situations, where your system shows you have components in stock that you don't actually possess. This eliminates confusion and ensures accurate production planning.

● Automatic Stock Adjustments: Manual stock adjustments are a recipe for errors. NIYAM automates adjustments based on real-time data, reducing discrepancies and saving valuable time.

● Physical Stock Reconciliation: Regularly reconcile your physical stock with NIYAM's records. This ensures your system accurately reflects actual inventory levels, leading to better decision-making.

● Stock Ledger: Maintain a detailed record of all inventory movements with NIYAM's comprehensive stock ledger. This offers complete transparency and simplifies audits.

2. Streamlining Purchase Management:

● Effortless Purchase Indent Creation and Approval: NIYAM streamlines the requisition process. Employees can easily create purchase indents, which can then be reviewed and approved electronically, eliminating delays and paper-based workflows.

● Seamless Purchase Order Generation: Once approved, NIYAM automatically generates purchase orders with accurate details, saving time and minimizing errors.

● Efficient Receipt of Material: Manage incoming materials with ease. NIYAM helps track deliveries, ensuring you receive the correct components and quantities.

3. Simplifying Sales Management:

● Effortless Sales Order Generation: Create and manage sales orders with ease. NIYAM provides a user-friendly interface to capture customer details, order specifications, and delivery schedules.

● Delivery Challan Creation: Generate delivery challans with accurate details to accompany your shipments. NIYAM ensures smooth order fulfilment and customer satisfaction.

● Partial Deliveries Made Easy: Handle situations where you need to fulfil orders in stages. NIYAM allows for partial deliveries with clear documentation, keeping your customers informed.

4. Empowering Production Management:

● Job Card Flexibility: NIYAM caters to both in-house and outsourced production models. Create job cards with detailed instructions and track progress efficiently.

● Real-Time Wastage Tracking: Minimise material waste. NIYAM allows you to track component usage and identify areas for improvement, leading to cost savings.

● Multi-Level Bill of Materials (BOM): Manage complex product structures with ease. Create multi-level BOMs that clearly define the components needed for each assembly stage.

5. Bill of Materials (BOM) Management:

● Multi-Level BOM & Category Tree: Create complex BOMs with multiple levels, ensuring all components are accounted for. The multi-level category tree feature allows for better organisation and easy access to specific components.

● Item Package & Alternate Parts: Manage different packaging options for the same component and define alternate parts for added flexibility in your production process.

● Design Files & Item Images: Store design files and images directly within the BOM for each component. This provides easy access to crucial information and reduces the risk of errors.

6. Gaining Valuable Insights with Analytics & Reporting:

● BOM & Item Availability Reports: Never be surprised by stockouts again. NIYAM provides real-time reports on BOM and item availability, enabling informed production planning.

● Audit Logs: Maintain a transparent record of all system activity. NIYAM's audit logs provide a clear historical view of actions taken within the software, ensuring accountability.

● User Management: Manage user access and permissions with ease. NIYAM allows you to grant specific roles and access levels to different users, ensuring data security and system integrity.

7. Additional Features:

● Projects: Manage ongoing projects and track their progress within NIYAM.

● Customer Support: Access dedicated customer support to ensure you get the most out of NIYAM.

● Minimum Learning Curve: Niyam's user-friendly interface is intuitive and requires minimal training for your team. This translates to faster adoption and quicker realisation of the benefits Niyam offers.

● Reduces Manpower Cost: By automating tasks and eliminating manual data entry, Niyam reduces the need for additional manpower. This translates to significant cost savings that you can reinvest in growing your business.

● Thrive for Zero Error: Manual processes are prone to errors, leading to delays and wasted resources. Niyam's automated workflows and real-time data minimise errors, ensuring quality and consistency in your production process.

NIYAM's Influence on Industry Automation

NIYAM acts as a stepping stone towards greater automation in the electronics manufacturing industry. By simplifying complex processes, reducing manual data entry, and providing real-time data on operations, NIYAM lays the groundwork for future automation integration. This allows MSMEs to leverage automation technologies like pick-and-place machines or automated soldering systems more effectively, eventually paving the way for a more automated and efficient production environment.With Niyam, you can:

● Focus on Growth: By streamlining operations and minimising errors, Niyam frees you to focus on strategic initiatives that drive business growth.

● Scale with Confidence: As your business expands, Niyam scales with you. Its flexible architecture can accommodate your growing needs and production volume.

● Gain a Competitive Edge: In today's competitive market, efficiency is paramount. Niyam equips you with the tools and insights you need to optimise production, reduce costs, and deliver high-quality products faster.

Are you ready to “Sync Your Operations” with NIYAM and enter into a world of possibilities? Get in touch with us today to learn more about how NIYAM can help your electronic manufacturing business achieve new levels of success and profitability.