The modern industrial landscape is undergoing a transformation fueled by automation. At the heart of this revolution lies a seemingly simple yet critical component: the process display. These displays act as the eyes and ears of human operators, providing real-time data visualization and control over complex industrial processes. But why are process displays becoming so integral to modern industry? Let's dive deeper.

Beyond Basic Monitoring: A Shift in Functionality

Traditional monitoring systems often relied on gauges and physical readouts, limiting the ability to grasp the bigger picture. Process displays bridge this gap by offering:

● Real-time Data Visualization: Complex data is presented in clear formats like charts, trends, and gauges, allowing operators to understand process dynamics and identify potential issues quickly.

● Enhanced Monitoring Capabilities: From temperature and pressure to flow rates and energy consumption, process displays provide a comprehensive view of critical parameters, enabling proactive intervention before problems escalate.

● Alarm Management: Configurable alerts warn operators of critical situations exceeding set limits, ensuring timely response and preventing costly downtime.

● Process Control: Operators can directly adjust setpoints, initiate commands, and control equipment through the display interface, streamlining process management.

● Data Logging and Reporting: Historical data is recorded for analysis, troubleshooting, and performance optimization, enabling data-driven decision-making.

● Interactive Training and Support: Intuitive interfaces and on-screen resources provide operators with training materials and support, facilitating faster learning and improved skill development.

Benefits Beyond Efficiency: Addressing Modern Challenges

Industry 4.0, characterized by interconnected systems and data-driven insights. Figures suggest that the worldwide Industry 4.0 market, covering sophisticated manufacturing automation and data exchange technologies, is forecasted to grow substantially at a Compound Annual Growth Rate (CAGR) of 16.9% from 2021 to 2026. But how Process Displays are impacting this ? The advantages of process displays extend beyond just improving operational efficiency. They offer solutions to some of the key challenges faced by modern industry:

● Boosted Productivity: A McKinsey & Company study found that automation solutions with real-time data visibility can increase productivity by up to 25%. Process displays provide this critical visibility, allowing operators to optimize production processes and minimize errors.

● Enhanced Quality: According to a report by the International Society of Automation, automation with real-time process monitoring can lead to a 20% reduction in product defects. Process displays enable real-time monitoring and control, ensuring consistent process parameters and higher quality products.

● Reduced Costs: An Accenture study revealed that automation solutions leveraging data analytics can generate cost savings of up to 30% through improved efficiency and reduced waste. Process displays contribute to these savings by facilitating preventive maintenance, reducing downtime, and optimizing resource allocation.

● Data-Driven Decisions: Research by MIT Sloan Management Review found that companies that leverage data analytics for decision-making experience a 5-6% increase in profitability. Process displays provide the data foundation for this approach, empowering companies to make data-driven decisions that optimize processes and improve profitability.

● Sustainable Manufacturing: A World Economic Forum report highlights that digitalization of manufacturing processes can contribute to a 15% reduction in energy consumption by optimizing operations. Process displays can play a vital role in sustainable practices by enabling real-time monitoring of energy consumption and identifying opportunities for optimization, leading to a reduced environmental footprint for manufacturers.

● Enhanced Connectivity: Modern displays connect seamlessly with other devices and systems within the Industrial Internet of Things (IIoT), facilitating real-time data exchange and remote monitoring/control. A key communication protocol enabling this connectivity is MODBUS. It's a widely adopted serial communication protocol that allows different devices from various manufacturers to talk to each other. This standardisation simplifies communication within the complex IIoT ecosystem.

● Predictive Maintenance: Data collected by process displays can be used for predictive maintenance strategies. By identifying potential issues early, companies can prevent equipment failures and ensure optimal uptime.

A Glimpse into the Future

As automation evolves, process displays will too. Here's what we can expect:

● AI and Machine Learning Integration: Process displays may integrate with AI and machine learning algorithms to provide operators with predictive insights and recommendations for process optimization.

● Augmented Reality (AR) Overlays: AR overlays projected onto process displays could provide real-time information about equipment status, maintenance procedures, and troubleshooting steps, further enhancing operational efficiency and safety.

Process displays are no longer optional extras. They are essential tools for modern industry, for driving success in the age of automation. In today's dynamic industrial landscape, companies need reliable and adaptable solutions.

Accelerate Revolution in Industry Automation with Instrutel Process Displays

Instrutel stands as a leading provider of process displays, offering a wide range to suit diverse applications.

Instrutel's commitment to customization ensures displays integrate perfectly with existing systems or facilitate the creation of entirely new ones. Compatibility with industry-standard protocols like MODBUS guarantees seamless communication within complex IIoT setups.

Understanding that visibility needs vary, Instrutel offers displays in sizes ranging from compact 1-inch displays for close-up viewing to expansive 12-inch displays for long-range visibility.

But functionality isn't the only concern. Instrutel recognizes the importance of aesthetics, meticulously designing displays that are not only functional but also visually appealing.

At present Instrutel manufactures displays for the following requirements-

1) Production lines

2) Process Parameters

3) Parking Applications

4) IoT Applications

Check our range of Process Displays here :

1. PRODUCTION LINE DISPLAYS :

Production displays facilitate real-time communication between managers and shop floor employees, conveying managerial directives to all staff. Additionally, they aid in coordinating production activities effectively.

Features :

● 6” to 10” Seven Segment Size range

● RS485 Interface

● Customised to any production process

● Optional Data Logging of events

● Digital and Analog Inputs

● Auto and Manual modes are available

● Auto reset options for every day and month

2. DOT MATRIX DISPLAYS :

These displays are designed to showcase safety messages and monitor critical parameters using dot matrix technology.

Features :

● 96X16 Dots

● 730X120 mm Display Area

● Power Supply 230V

● Power Consumption 8 Watts

● RS232/RS485 Port

● Instrument Parameter Monitoring Using Modbus Protocol

3. PROCESS PARAMETER DISPLAYS :

A process parameter display shows real-time data on factors like temperature, pressure, and flow rate in industrial processes.

Features :

● Industry standard RS485 Modbus RTU protocol on RS 485 bus

● User configurable baud rate and ID

● Multiple displays on same bus displaying different parameters

● Customised display size from 1 inch to 12 inch

● Outdoor /Indoor applications

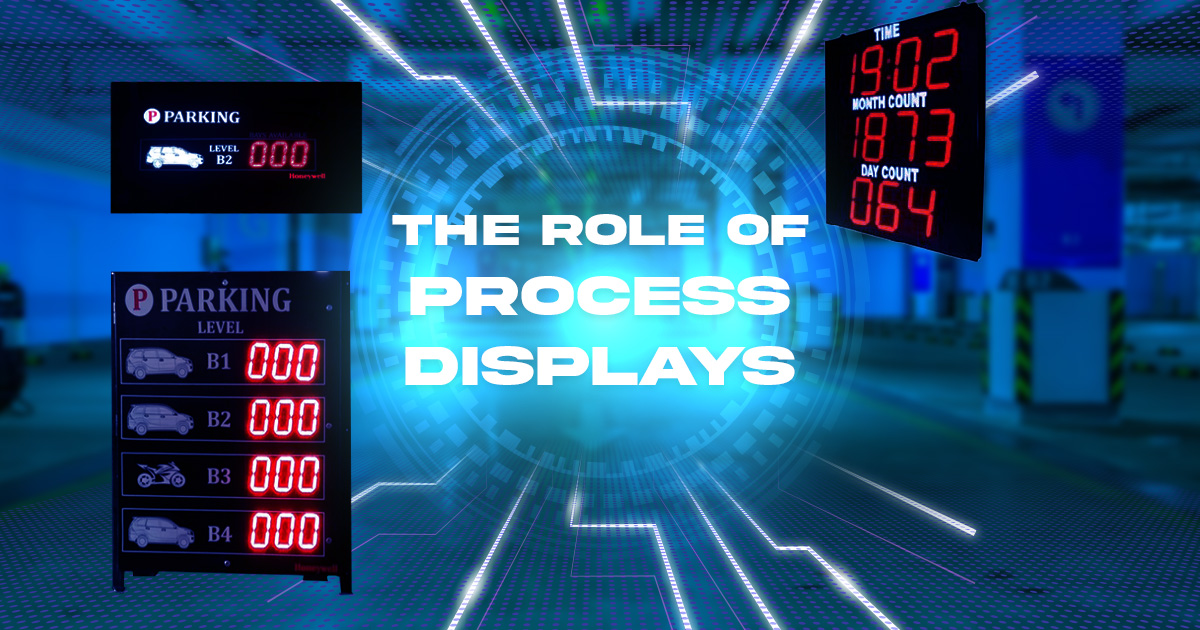

4. Parking Displays :

Parking lot displays are digital screens or signs installed in parking lots to provide real-time information about available parking spaces, directions to different areas within the lot, and other relevant information such as rates and regulations.

Features :

● Operating Voltage: 230V

● Power : 30 Watts

● Viewing Angle : 30deg

● Size of Display : 6 inch

● Enclosure : Aluminium Cover with MS BackPlate

● Type of Enclosure : IP55

● Interface : Isolated RS485

● Protocol : MODBUS RTU

● Baud Rate : Configurable- 4800,9600,19200,38400,57600

● Dimensions : As per customer requirement

● Mounting : Hanging

As Industry 4.0 unfolds, process displays will continue to evolve, offering a window into the complex world of industrial processes and ensuring continued growth and efficiency in the years to come. Trust us for the latest technologies and convenient choices. Ready to stay ahead of the curve with Instrutel and embrace the latest industry advancements?